Advancements To Space Technology

by Matthew Karuna Lim, Saw Ze Dong, He Ziqi

26 Aug 2019

Introduction

July 2019 marked the 50th anniversary of the moon landing. While the world has had much scientific and technological advancements since then, let’s check out what’s new.

About 3D Metal Printing

A number of different technologies are rising and currently, one of the most prominent steps the space industry has already taken is to introduce industrial-grade 3D metal printing into their industry. It has proven itself to be very cost-effective, efficient, which make this technology of metal printing the crown jewel of the commercial race to space.

Uses of 3D Metal Printing for Space

Designing durable hardware for space is a difficult and daunting task. Outer space requires function, performance and high precision, unlike anything required on Earth. With the help of metal additive manufacturing, engineers are now able to design and produce hardware that is able to overcome the challenges of outer space, with faster iterations and faster product development.

3D Metal Printed Part

Current Uses of 3D Metal Printing

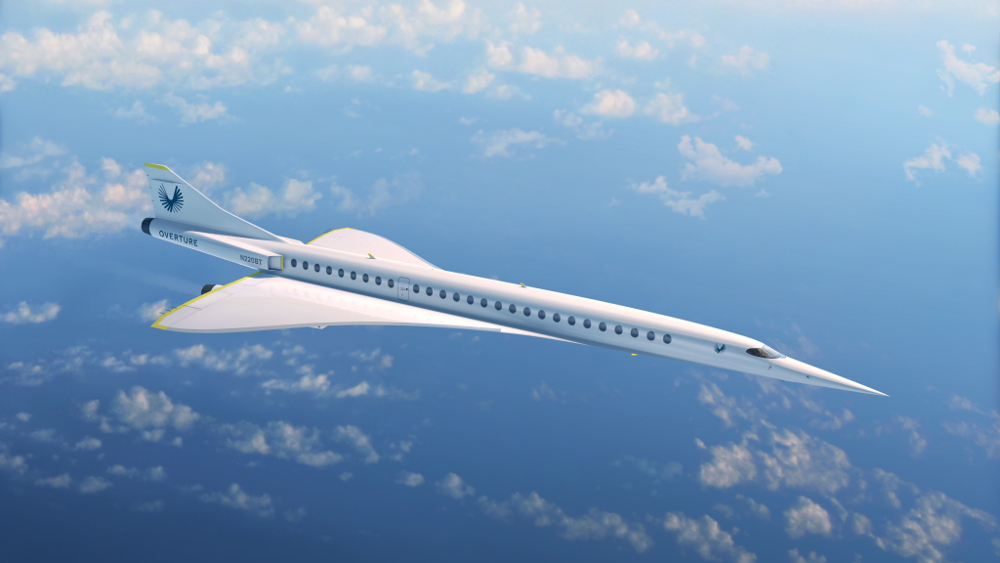

Recently, 3D metal printing was selected to manufacture flight hardware for Boom Supersonic’s XB-1, a jet that was able to travel at 2715 kilometres per hour. Metal additive manufacturing allowed Boom to produce the necessary parts more efficiently, with increased precision and much freedom of design.

Boom Supersonic’s XB-1

Benefits of 3D printing

3D printing also greatly lowers the cost of commercial space activities by continuing to drive the development of advanced materials, including metal replacement, high-performance polymers and composites. The possibility of 3D printing in space allows the convenience of planet colonization in the near future, which may allow astronauts to conveniently set up facilities and machinery such as rovers.